The original Industrial Revolution, which began around 1760 which is also called Industry 1.0 was based on the division of labor and driven by steam/hydro power. Industry 2.0 was based on electric power, which was a major innovation. We are now at the edge of Industry 3.0 which has been primarily driven by Information and communication technologies (ICT) enabling both manufacturing and service sectors.

The intelligent sensors of today, RFID, such ‘Cyber-Physical’ systems and the internet of things (IoT) are transforming the manufacturing sector across the entire supply chains. A key component of such changes is decentralized control: Intelligent components operate in each stage of the system through which a part, order or information moves. In this type of process, communication occurs at each step to determine what value/ information/ decision to add/ process/ implement. Decentralized control makes it easier to add/ process/ implement as needed, making it smoother to meet the increasing customer demands. Slowly but surely, we are gradually moving to Industry 4.0.

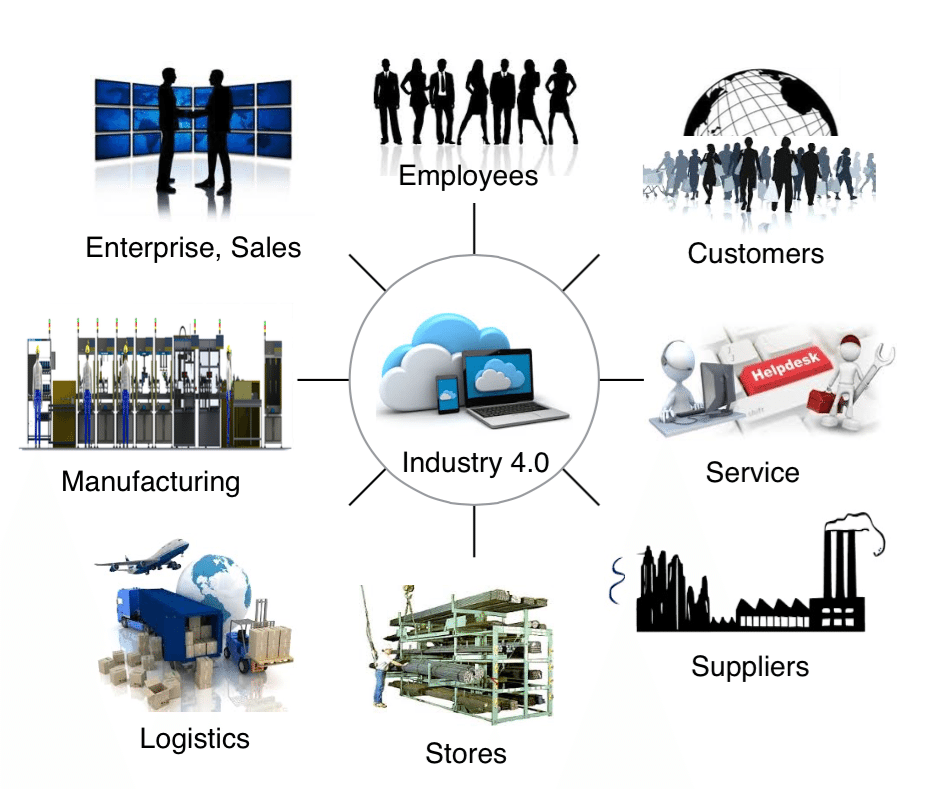

Industry 4.0 is driven by smart technologies coupled with the internet of things/ services. It offers a seamless integration of various technologies such as cloud, big data, robotics, virtualization, smart devices, additive manufacturing (for example, 3D printing), and so on. It enables to connect machines, devices, and people at anytime, anywhere and at any place.

EMYRAS, with over a decade of experience in providing automation to the manufacturing industry and with the core expertise in software related solutions, connecting manufacturing to the enterprise, we are investing in technologies for the Industry 4.0.

INDUSTRY 4.0 :-

- Process Traceability

- Part Traceability

- Preventive Maintenance

- Online Process Capability (Cp, Cpk)

- Machine Capability (Gage R&R)

- Mfg Execution System (MES) I/F

SMART MANUFACTURING FACTORIES…!

CONVERGING TOWARDS INDUSTRIAL REVOLUTION INDUSTRY 4.0 :-

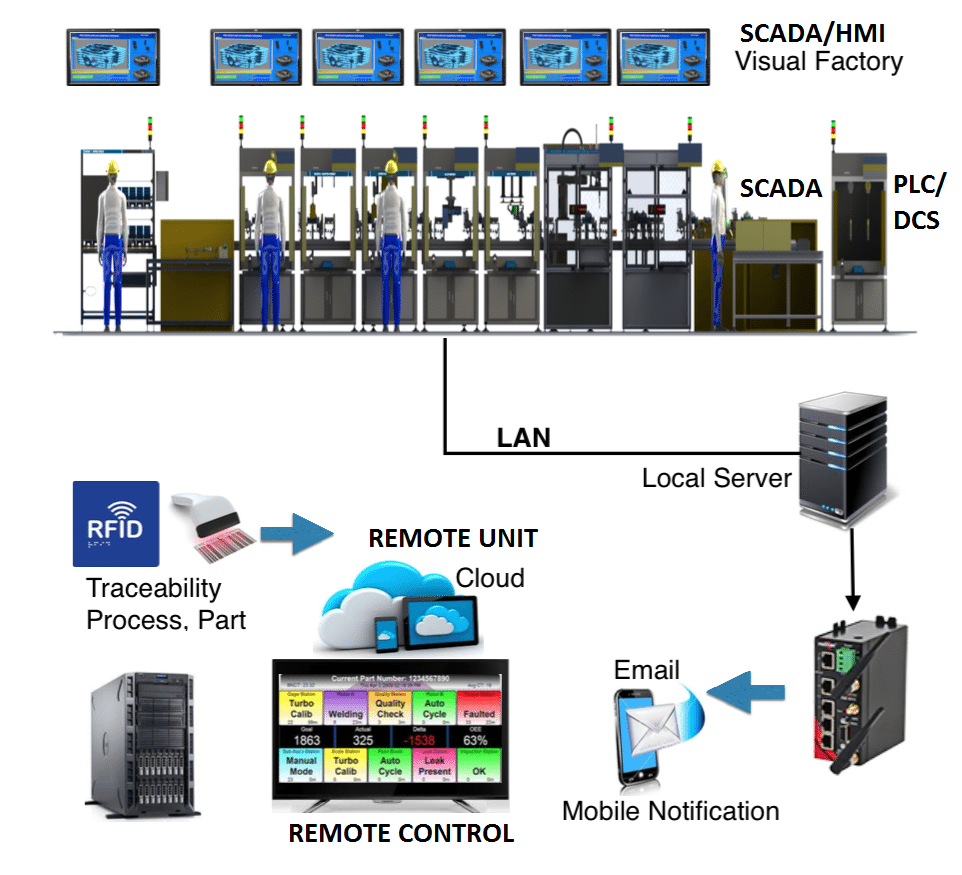

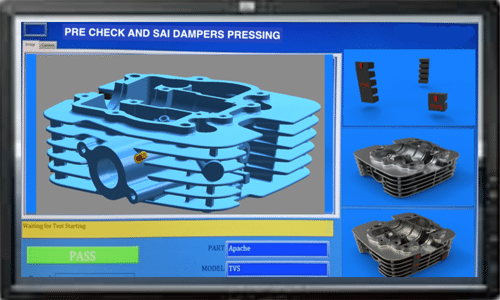

LeanMate, Fastest, Isight are Smart Machines. The machines not only perform an operation, it also checks & take a decision on the quality, acquire process data, provides visibility of the operation, the status of the machine, online process capability, production data and report the DEE schedules and alerts preventive maintenance. Integrated Health Management System can prevent machine breakdowns.

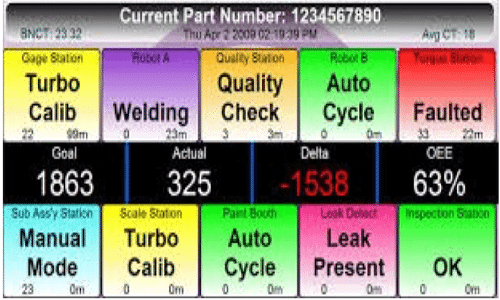

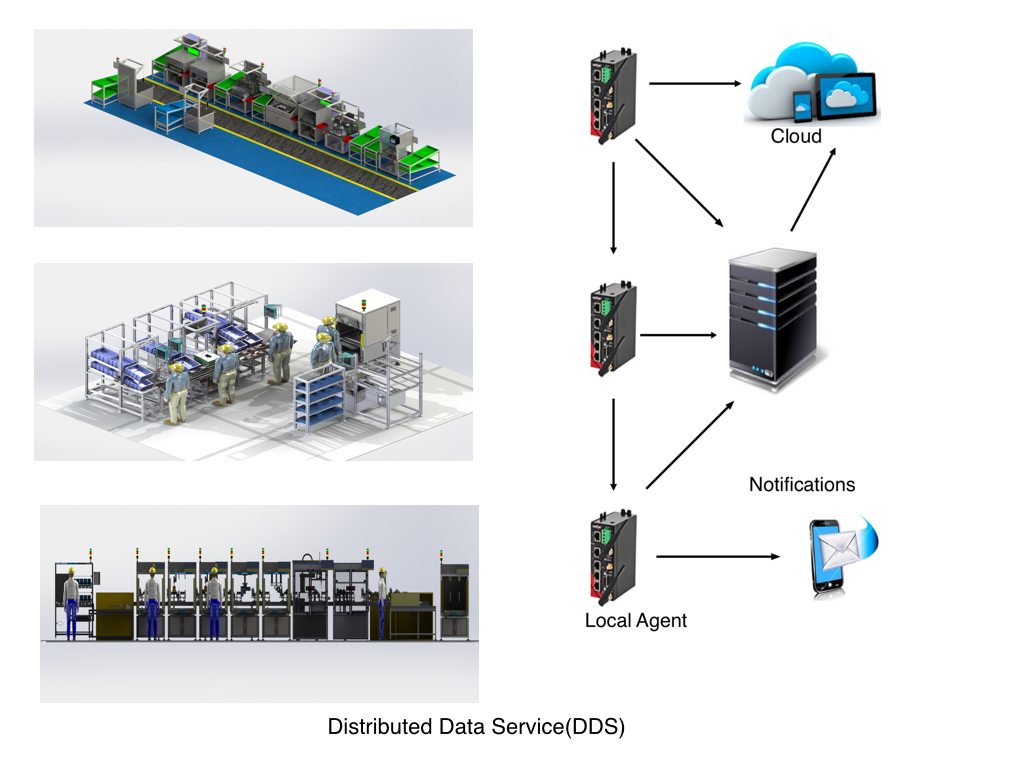

The immense amount of data the process can be analyzed and displayed on a local ANDON display which can show the productivity, process quality, line status etc… This can also be connected to MES/ERP system and production scheduling, KANBAN can be made Seamless. And it also pushes the data to the cloud as required, finally Converging towards Industry 4.0.

SMART MACHINES – FUTURE IS NOW !

- Machine Capability (Gage R&R)

- Mfg Execution System (MES) Interface

- Operator Guidance (Digital SOP)

CONNECTED LEAN MATE FACTORY CLOUD

VISUAL FACTORY:-

KPI & ALERTS:-

- Digital SOP (Animation), FAQ

- Machine Status, Takt

- In-Process Capability (Cp, Cpk)

- Machine Vision

- Productivity Data

- Preventive Maintenance Alerts

- Integrated Health Management

- Overall Equipment Effectiveness (OEE)

CONVERGENCE TO INDUSTRY 4.0 DISTRIBUTED DATA:-

- Operator Guidance (Digital SOP)

- Machine Integrated Health Management

- Advanced Visual Factory

- Advance Andon Display

- Smart SMED